By Geoff Hunt, Audio and Visual Curator

Texas has changed quite a bit over the years, as is readily seen in our vast photograph and postcard collections. To help bring some of those changes to life, we’ve created a “Texas over Time” blog series that will illustrate the construction and renovations of buildings, street scenes, and more. Our collections are especially strong on Waco and Baylor images, but look for some views beyond the Heart of Texas, too.

From the Bluebonnet Ordinance Plant to Rocketdyne and SpaceX, scientists, engineers, and production workers have almost continually been at work in McGregor, Texas, since October of 1942, helping win wars, achieve space flights, and work towards lunar missions. President John F. Kennedy had a goal to put men on the moon in the decade of the 1960s, and on July 20, 1969, this goal was achieved. In Rocketdyne’s company newsletter, Skywriter, they announced “Rocketdyne Engines to See Finest Hour During Apollo 11 mission…” The company stated that the moon landing “will be a triumphant climax to 10 years of hard work by Rocketdyne employees.” These 10 years included hard work that was done in Central Texas, in the city of McGregor, and the people at the Rocketdyne Facility made significant contributions to space flight and exploration. With the 50th anniversary of the Apollo 11 moon mission on July 20, 2019, a look back at a Central Texas connection may help shed light on this area’s contribution to this historic technological achievement.

In its early years, the McGregor facility was home to Bluebonnet Ordinance Plant, established in 1942 by the U.S. Department of Defense (U.S. Army Ordinance Corps) to help build bombs for the war effort. From October 1942 to August 1945, Bluebonnet had 6 lines of production and made a total of 13.8 million bombs and explosive boosters at the facility. The 18,000-acre Bluebonnet plant employed roughly 5,000 men and women and was referred to as a “city within a city (McGregor).” It had many internal functions including security forces, medical personnel, cafeterias, and housing facilities. Upon vacating, the land was especially valuable to later government contractors as its infrastructure could house ordinance for storage and had space that allowed for rocket testing.

While ordinance only manufacturing ceased at the end of World War II in 1945, the well-used plant in McGregor was destined to serve the nation once again. In 1952, the property was acquired by the U.S. Air Force, named AF Plant 66, and was operated by Phillips Petroleum Company-Rocket Fuels Division, until 1958. For a short time, PPC partnered with North American Aviation forming Astrodyne, Inc. In 1959, NAA bought PPC’s share and that year Rocketdyne Solid Propulsion Operations took over the rocket fuel testing and engineering facility at the McGregor site, operating until 1978. Later contractors included Hercules, operating from 1978 to 1995, Beal Aerospace, and at the time of this writing, SpaceX.

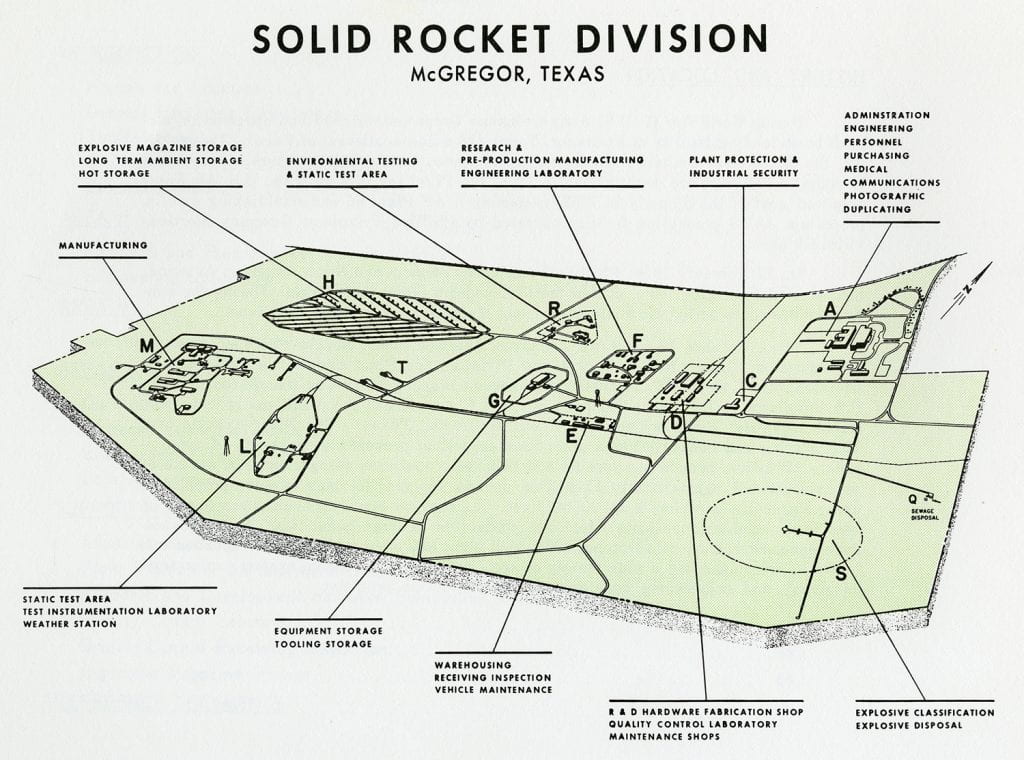

As a large company with production facilities besides the McGregor plant, Rocketdyne emerged during a time of rapid change and technological development. After World War II, the U.S. Defense Department contracted with North American Aviation to begin researching Germany’s V-2 rocket and sought to adapt its burners and fuel systems to match U.S. standards. North American Aviation/Rockwell later formed the Rocketdyne Division in 1955 to specialize in this type of work. Their main focus was chemical propulsion in solid, liquid, and hybrid propelled rocket motors and engines. Most notably, the company was a supplier of rocket engines to NASA. It had headquarters in Canoga Park, California, with operations in Missouri, Nevada, and McGregor, Texas. Each facility had distinct functions and contributed heavily to the U.S. space program as well as the Department of Defense. In October 1959, when Rocketdyne moved into the McGregor facility, the company reported: “The full acquisition of the solid propulsion operations at McGregor…resulted in a significant strengthening of Rocketdyne’s capabilities for research and development of advanced solid propellants by the close coordination of research activity between the Canoga Park, California, and McGregor, Texas laboratories.”

By about 1960, McGregor could static test “small-scale rocket motors” with up to 5,000 pounds of thrust and 5,000 pounds of propellant at the facility’s multiple firing bays. Production was also possible and included JATO (Jet Assisted Take Off) rockets for the U.S. Air Force. McGregor and Canoga Park coordinated closely in their research and engineering and in 1966 were using “remote terminals used by engineers consisting of 35 teletypewriters transmitting programs and data over leased lines connecting McGregor, TX., to the main Rocketdyne computer in Canoga Park, CA.” By the late 1960’s, the McGregor plant had produced over 250,000 rocket motors and thousands of gas generators and igniters. Some examples the company produced at their multiple U.S. sites include: Navaho, Redstone, Thor, Atlas, and Saturn 1B. These evolved into the Saturn V rocket (launch vehicle) used in NASA’s Apollo Missions including the 1969 moon landing.

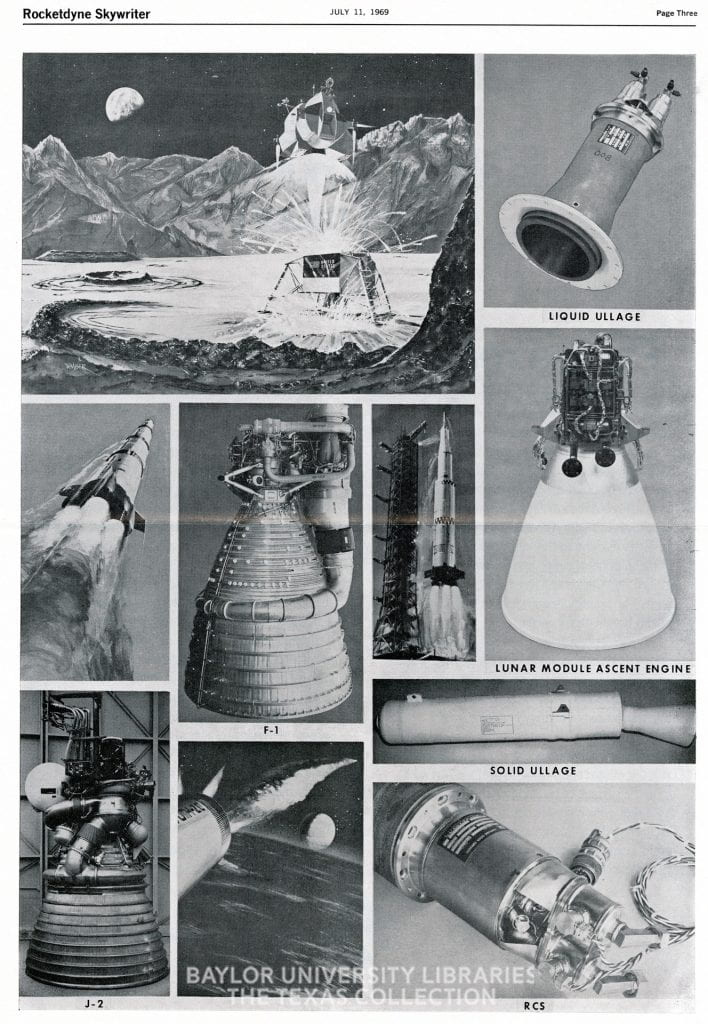

The first stage of the Saturn V launch vehicle that carried the Apollo and crew included five Rocketdyne F-1 rocket engines producing 7.5 million pounds of thrust. NASA reports that the F-1’s five engines burned “42,500 gallons of fuel per minute;” the propellant was RP-1, kerosene, and liquid oxygen. Saturn V also included 6 Rocketdyne made J-2 engines powering the 2nd and 3rd stages. This massive launch vehicle for Apollo 11 totaled over 80 rocket engines used in various stages to propel astronauts into space orbit and then to the moon. The Saturn V rocket was used a total of 13 times with 10 missions. It even launched NASA’s first space station, Skylab, into space in 1973. The engineering, testing, and production of rockets in McGregor, helped this nation achieve it goals in the 20th century.

Throughout the years and through various operators, countless scientists, engineers, and production workers have called Central Texas home in order to work in the McGregor facility. With the SpaceX acquisition of some of this property in 2002-2003, rocket testing is still done here at the former Bluebonnet Plant (see SpaceX’s Falcon Heavy) and it has stood the test of time adding to the rich history of Central Texas.

The “Then and Now” slider shows the former Bluebonnet Ordinance Plant as it stood in this aerial photo from 1952; a section was cropped at lower portion to compare today. The recent (June 2019) picture from Google Earth, shows SpaceX covering some of the same land, buildings, and spaces of the former WW2 era production facility. The arrow-shaped area known as “H” is the most distinctive portion seen in the aerials and is still present.

1940’s McGregor, Texas-Map of Bluebonnet Ordinance Plant: From October 1942 to August 1945, the Bluebonnet Ordinance Plant had 6 lines of production and made a total of 13.8 million bombs and explosive boosters at the facility. The 18,000-acre Bluebonnet plant employed roughly 5,000 men and women and was referred to as a “city within a city (McGregor).” Since after the war, the property and its facilities continue to serve many ordinance related and rocket manufacturing purposes. Map from master’s thesis: “A Sociological Study of the Bluebonnet Ordnance Plant at McGregor, Texas,” The Texas Collection, Baylor University.

CHECK OUT THIS FLICKR SET FOR MORE PICTURES OF Rockets with Roots in McGregor, Texas

Works Cited:

1958 Annual Report, North American Aviation, Inc. (Publication), The Texas Collection, Baylor University.

Solid Propulsion Facilities, Rocketdyne-A Division of North American Aviation, Inc., Solid Propulsion Operations, McGregor, Texas, March 1960-Report No. R4036. (Publication), The Texas Collection, Baylor University.

This is Astrodyne, Inc., Astrodyne in McGregor, Texas. (Publication), Lloyd Gholson Rocketdyne collection, The Texas Collection, Baylor University.

Solid Propellant Research and Development, Rocketdyne, A Division of North American Aviation, Inc. (Publication), Lloyd Gholson Rocketdyne collection, The Texas Collection, Baylor University.

Solid Rocket Division Facilities, North American Rockwell, 1966, BTI 70-18. (Publication), Lloyd Gholson Rocketdyne collection, The Texas Collection, Baylor University.

Solid Rocket Division Facilities, Rocketdyne, March 1967, R-4300-1. (Publication), Lloyd Gholson Rocketdyne collection, The Texas Collection, Baylor University.

“Aviation Week Advertises Rocketdyne Achievements,” Skywriter-Rocketdyne Division, April 2, 1971. (Newsletter), Lloyd Gholson Rocketdyne collection, The Texas Collection, Baylor University.

Corrie, Walter Samuel Jr., “A Sociological Study of the Bluebonnet Ordnance Plant at McGregor, Texas,” Thesis for M.A., Baylor University, May 1948, The Texas Collection, Baylor University.

No Comments